Naše produktové portfolio je možné rozdělit na dvě základní části. Jsou to dodávky výkovů pro strojírenský průmysl (výrobci stavební techniky, energetických zařízení, výrobních strojů, ložisek, apod.) a dodávky výkovů pro kolejovou dopravu (obruče pro tramvaje, vlaky a metro, přítlačné kroužky, nápravy, atd.).

Z pohledu použité technologie vyrábíme zápustkové výkovky rotačních tvarů (kruhy, příruby, apod.), volné výkovky (lišty, hřídele, kruhy, kotouče, děrované kotouče, ojnice, táhla, vřetena, kostky, atd.), ale v současné době především bezešvé rozválcované kruhy (hladké kruhy, tvarové kruhy, příruby, atd.). Společnost TRIANGOLO spol. s r.o. disponuje kompletním výrobním řetězcem, tzn. že na základě požadavku a dokumentace zákaznáka zajistíme realizaci požadovaného produktu od dodávky a přípravy materiálu až po

tepelné zpracování, obrobení a kontrolu v rámci vlastních výrobních kapacit

Od roku 1998 je naše firma pravidelně certifikována dle ISO norem a vlastní certifikát jakosti TÜV Management Service.

Další významný milník rozvoje naší společnosti se nachází v roce 2017, kdy jsme se stali součástí investiční skupiny ANACOT CAPITAL. Tento významný krok nám přinesl prostor pro rozšíření našeho výrobního a dodavatelského potenciálu díky využití synergických efektů v rámci celé skupiny. Nejvýznamnějším přínosem je však nastartování nové éry rozvoje celé firmy a to jak v oblasti obchodu a výroby, tak i v oblasti lidských zdrojů, inovací či modernizace strojního parku a budov.

ELFE, spol. s r. o. operates in Krnov in the Bruntál district. It was founded on 1.2.1993.

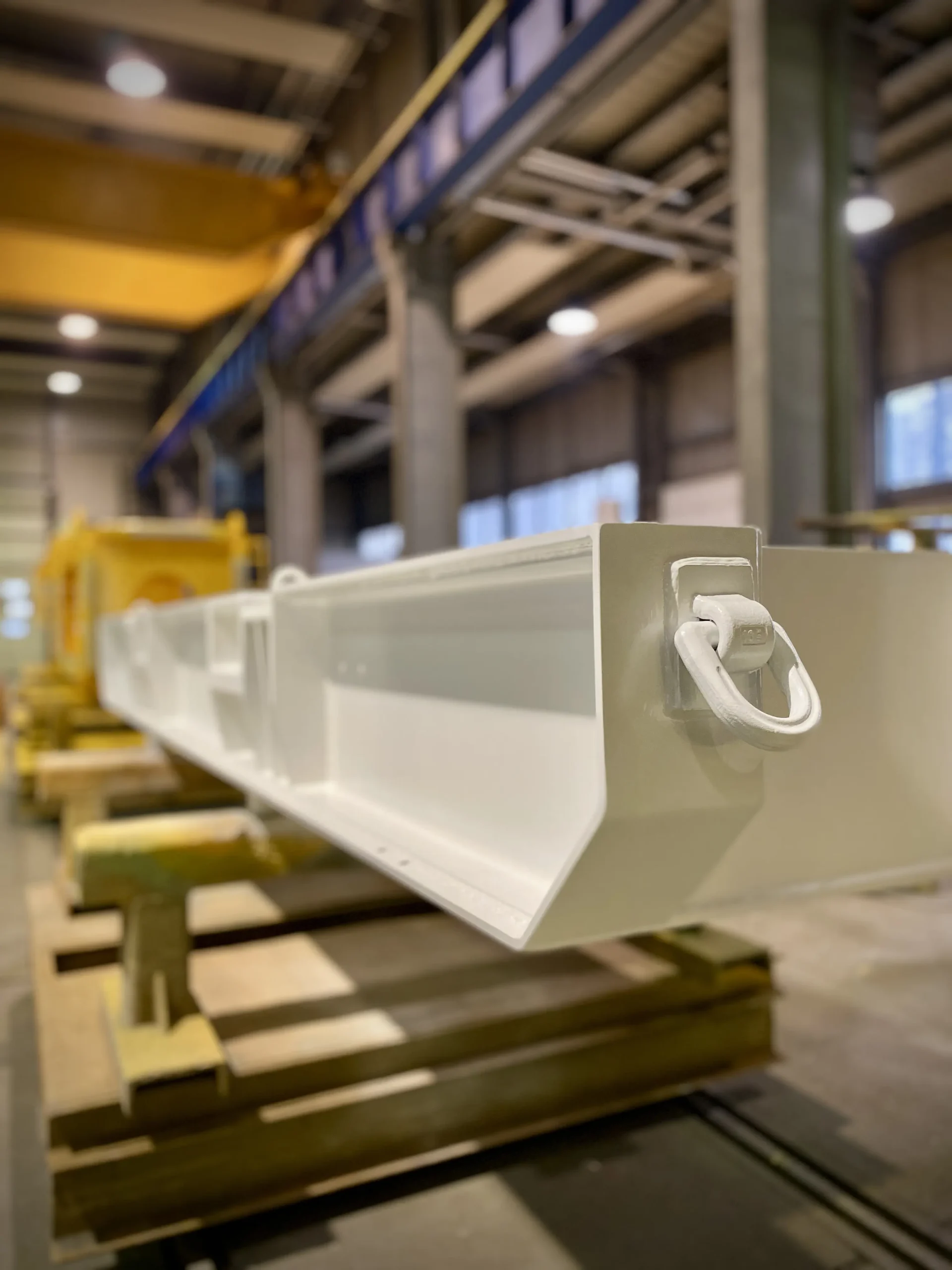

ELFE spol. s r.o. is an important, reliable, competitive and specialized supplier in the field of engineering units. Our customers are major global manufacturers of equipment for the extraction and transportation of oil, gas and minerals, marine handling equipment and transport technology. Our efforts are mainly focused on these areas:

We are improving our preventive approach to environmental and occupational health and safety issues and assessing the situation in accordance with current legislation – the ecology at ELFE is in compliance with environmental regulations.

© 2025 ELFE, s.r.o. All rights reserved.